Knowing how to handle & store gamma-butyrolactone safely is essential for any business or laboratory working with this versatile solvent. Because gamma-butyrolactone (GBL) is widely used in industrial cleaning, coatings removal, electronics processing, and polymer research, organizations must adopt clear safety and compliance protocols to protect both personnel and product quality.

The first step in understanding how to handle & store gamma-butyrolactone safely is to ensure that proper personal protective equipment (PPE) is always in use. Gloves, goggles, and protective clothing help reduce exposure risks, while proper ventilation minimizes vapor buildup. Workers should be trained to read and follow Material Safety Data Sheets (MSDS) and be familiar with emergency spill procedures.

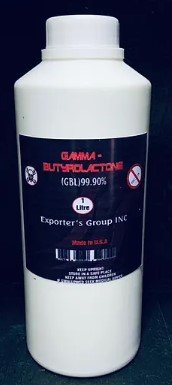

Storage is just as important as handling. GBL should be kept in sealed, clearly labeled containers in a cool, dry, and well-ventilated location. Direct sunlight, heat sources, or incompatible chemicals should be avoided to maintain product integrity. For bulk containers, suppliers recommend specialized storage cabinets or secured drums with secondary spill containment.

Compliance with OSHA, DOT, and EPA regulations ensures legal and safe use. Reputable suppliers provide full documentation, including Certificates of Analysis (COA), along with guidance on transport and disposal. Keeping accurate storage logs and training staff in handling procedures further strengthens workplace safety.

Ultimately, learning how to handle & store gamma-butyrolactone safely is not just about meeting regulations; it’s about protecting employees, safeguarding operations, and ensuring consistent results in industrial and laboratory applications. By working with reliable suppliers and maintaining strict safety protocols, companies can use gamma-butyrolactone effectively while minimizing risk.